Under the skin: The logic behind Bosch's plans for hydrogen fuel cell trucks

When a company the size of Bosch is poised to release a new technology, it's usually something to take seriously. Tier-one suppliers like Bosch are at the top of the supply chain to the automotive industry and are responsible (rather than the car manufacturers) for introducing much of the technology that makes all vehicles tick.

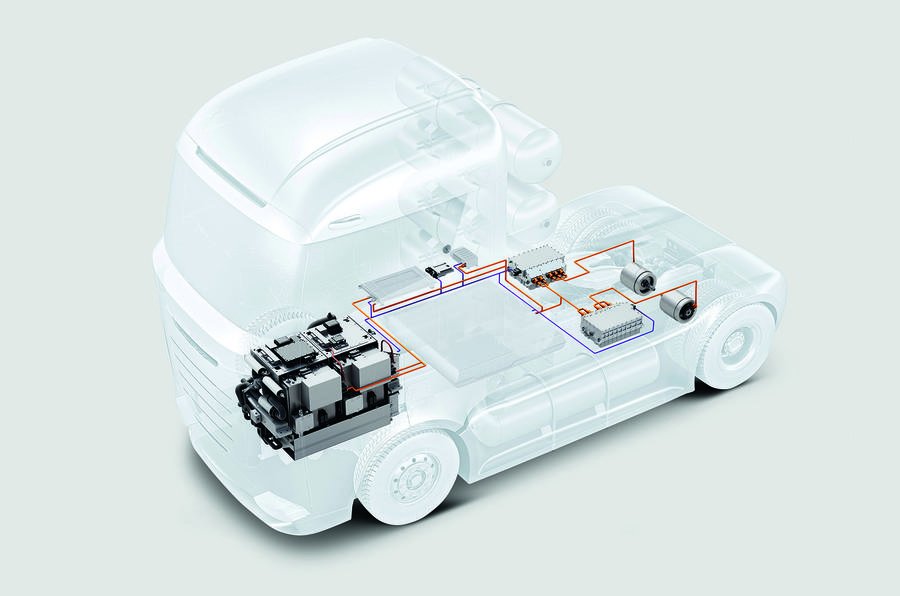

Bosch recently announced plans to start production of hydrogen fuel cell powertrains between 2022 and 2023, focusing initially on trucks. Once these are established in heavy vehicles, smaller-scale versions for cars can follow. Fuel cells convert hydrogen and oxygen from the air to electricity, heat and water, and using hydrogen produced from renewable energy makes the operation of a fuel cell vehicle carbon-neutral. Heavy trucks are a good starting point for the technology because batteries big enough to provide sufficient range would be huge in volume and weight, not to mention incredibly expensive.

Hydrogen has a high energy density and, because it's stored as a compressed gas in a fuel cell vehicle, its quantity is measured by weight, rather than volume. One kilogram of hydrogen contains about the same amount of energy as 3.3 litres of diesel. Bosch calculates that 7kg of hydrogen is enough to power a 40-tonne truck for around 60 miles. That means 35kg of hydrogen would be good for 300 miles.

Given that the battery in a premium electric car today can weigh more than 500kg, it doesn't take much imagination to work out that a truck battery capable of doing the same would be huge – unless there's a radical improvement in the energy density of current battery technology.

There's plenty of debate about the efficiency of hydrogen fuel cells compared with batteries, and there are two conflicting schools of thought. One is that feeding electricity (an energy source) straight into a battery is more efficient than converting it into hydrogen (an energy carrier) then back into electricity. The other, to which Bosch subscribes, is that electricity production and demand rarely coincide, so making hydrogen on a decentralised basis to store, rather than waste, surplus electrical energy makes the case for fuel cell vehicles. Bosch believes that hydrogen costs will fall in the medium term in order that running a fuel cell vehicle will be no more expensive than one with a conventional powertrain.

Tests over the decades have demonstrated hydrogen to be safe compared with liquid fuels, too. Hydrogen is 14 times lighter than air and volatile. In the right proportions, a mixture of hydrogen and oxygen can be explosive, but when hydrogen escapes from a vehicle, it rises too quickly to react with oxygen in the air. Hydrogen fires can be over in a flash and might not do much damage, whereas heavier-than-air, ground-hugging petrol fumes can easily cause explosive fires.

Fuel cell vehicles share pretty much the same electric driveline with battery-electric vehicles, so with a combination of both hydrogen and battery technologies, vehicle manufacturing could become more streamlined and increasingly sustainable.

Batteries in the afterlife

EV batteries still retain around 80% of their original capacity after 100,000 miles, and reports suggest the global storage capacity using second-life EV batteries could reach 275gWh by 2030. BMW UK is working with Off Grid Energy to create 40kWh mobile power sources, while the Smarthubs project of Groupe Renault and Connected Energy is installing 360kWh 'E-Stor' systems on commercial sites in the UK and France.

Related News