BMW's Neue Klasse Revolution Just Took A Big Step Towards Production

The first all-electric drivetrain to be produced at Steyr, the Gen6 motor, which debuts in the upcoming iX3 50 xDrive, will be built across two new lines dedicated to the e-drive’s core components, including the rotor, stator, transmission and the inverter. The housing will be produced at BMW’s sister plant, Landshut, in Hungary. It’s expected that the Gen6 lines will require up to 1,000 new employees at Steyr, and while the facility will continue to build petrol and diesel engines in parallel, up to half of the facility’s workforce could be dedicated to electric motor assembly by the end of the decade.

The Significance Of Gen6

Introduced in February this year, the Gen6 architecture is said to be “quanatum leap forward,” both over its Gen5 predecessor and for BMW’s new EV range as a whole. Developed with flexibility in mind, the Gen6 is built around a new nickel-manganese-cobalt (NMC) battery that uses cylindrical cells to make packaging easier. This means no modules are needed to fit them together, unlike contemporary EV battery packs. This modular concept not only allows the BMW Group to produce different electric drivetrains across its range, but the new cylindrical build is also up to 20% denser than the lithium-ion examples they replace.

This could increase EV range by up to 30%, and efficiency by up to 20%. Kia, for example, recently completed a test of its fourth-generation battery packs, which retains up to 70% of its life across the first eight years. Charging speeds should increase by up to 30%. To put that into perspective, BMW itself states how these changes would affect the iX3 if it were built with the same 800-volt architecture but with a Gen5 powertrain.

“Energy loss is reduced by 40%, costs by 20% and weight by 10%. All this makes a significant contribution to the approximately 20% increase in overall vehicle efficiency.”

- Martin Kaufmann, BMW Group

From a production standpoint, the Gen6 architecture could potentially halve production costs too.

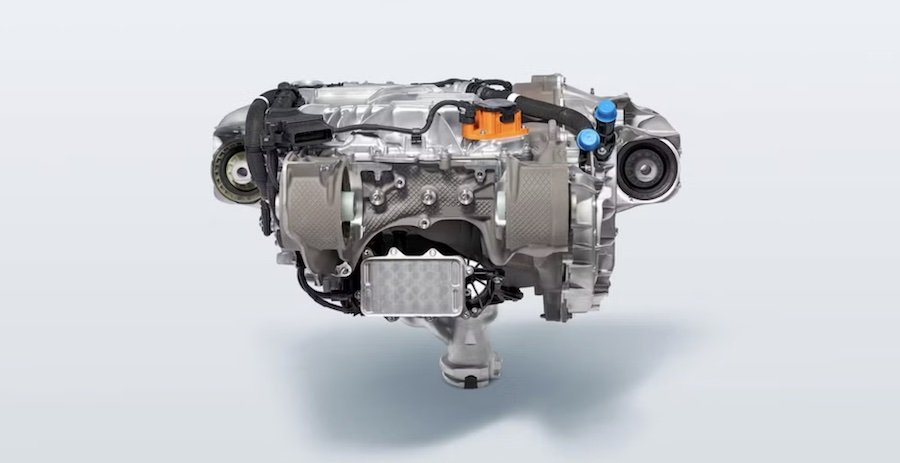

The Gen6 Electric Motors

The electric motors, meanwhile, comprise lighter and more efficient electrically excited synchronous motors (EESM), which were introduced with the first-gen iX3 in 2018. These work in combination with a small asynchronous motor (ASM) that weighs just under 155 pounds, and exclusively powers the front axle, giving BMW the option of quad and tri-motor drive for the first time.

The Gen6 motor is part of a €1 billion-plus (around $1.15 billion) investment from BMW between the project’s launch in 2022 and BMW’s plans for at least half of its global sales to come from emissions-free vehicles by 2030. Unsurprisingly, the Gen6 is expected to be used in the next generation of EVs from Mini and Rolls-Royce as well.

Verwandte Nachrichten